What are the materials for the soul to emerge? Types of soft coating: an overview of materials with a variety of technical and technological aspects

In front of us, we are looking forward to the roof. In addition to the standards for fallout, it is necessary to protect the moisture supply of the roof and water (with a complete blood system), as well as wind protection.

Another thing is the durability and absorbency of the future coating.

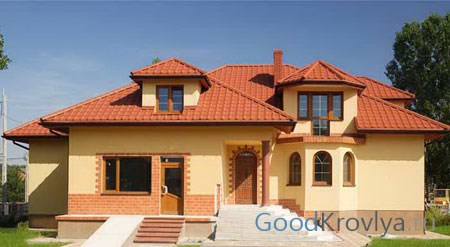

The third parameter is based on the architectural decision and is made with gusto. Ale can be found in the material itself (shape, texture, color). But not every cover will fit easily on your surface. For various types of roofing materials there are their own standards (for example, kuthilu), which are acceptable or unacceptable for the material to dry out.

Virobniks establish warranty terms on the coating in accordance with the rules of transportation, installation and operation. There are a lot of materials that can serve much longer:

- soft tiles - guarantee 15-20 years (actually 30-50 years);

- metal tiles -5-15 rocks (30-50 rocks);

- natural tiles – 20-30 rocks (100-150 rocks);

- slate (asbestos cement) - 10 rocks (30-40 rocks);

- bituminous leaves – 15 rocks (15-25 rocks);

- coating steel and corrugated sheeting – 15-20 rubles (up to 50 rocks);

- slate roofing – 30-40 rocks (150-200 rocks);

- seam covering – 15-20 layers (up to 50 layers).

Roof tiles (ceramic, cement-sanded, bitumen)

This clay mass is formed after kilning. The resulting color of the tiles is red-brown. The size of the slabs is small (30x30 cm), and the skin weight is about 2 kg. Ceramic tiles come in: rows, flat stitches, groove stitches, stamped grooves, single-stitched and double-stitched.

The standard fastening of such tiles is set at angles between 22 and 60 degrees. Above all, additional fastenings are required, and below that, increased ventilation and waterproofing.

Pros:

- minimal cleaning requirement (grooves, grooves) during operation;

- soundproofing;

- resistant to heat, corrosion, extreme frost resistance (1000 or more cycles);

- variety of decor (shape, color);

- Due to the porosity of the material, the vologger is easily evaporated in the air.

Disadvantages:

- great is the vaga, for which the maximum value is required Krokwiana system with a small amount of elements;

- crankiness;

- When ventilating folding doors, additional fastenings and waterproofing are required.

This is an alternative version of the front look of the cover, which does not seem to be affected by anything. It is both convex and flat. The working temperature is 20 to 60 degrees. A great advantage is that such tiles with rocks gain value and do not lose their power.

Pros:

- resistance to aggressive media, including radiation;

- Frost resistance 1000 cycles.

Disadvantages:

- massiveness (weight 1 cm);

- Possible damage if transported incorrectly.

It is made up of bitumen tiles coated with fiberglass, cellulose, polyester and a special farbe. Based on the bitumen-hum ball, the tiles are tightly pressed against the seam sheets, creating a permanent waterproofing. It also has good plasticity, so you can bend it with your hands as you wish (this is especially necessary with a folding cover). The vibration is extremely strong: 12 degrees to the maximum.

Pros:

- not flexible to the point of bruhtu, but of plasticity;

- breadth of application: suitable for any kind of tricks and forms of dahu;

- soundproofing;

- not susceptible to corrosion and rot.

Disadvantages:

- high flammability;

- resistant to ultraviolet radiation (blooms in the sun);

- not suitable for winter installation.

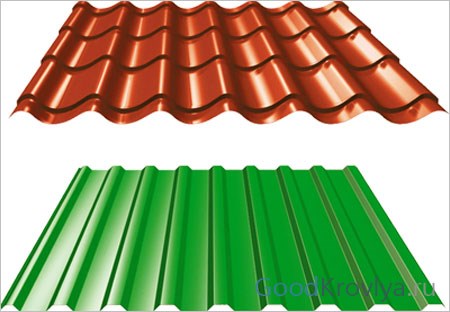

We decided to introduce metal tiles under this heading, since it is already widespread and popular. It is a sheet of galvanized steel, coated with polymer. From a distance one can see that the texture is made up of several “tiles”, but in fact a whole sheet from a pneumatic meter, of any size (depending on the size of the skin part, the leaves can be To celebrate a special day). Suitable for any kind of treatment, starting at 15 degrees. At temperatures up to 20 degrees, it is important to seal the sticks.

Pros:

- high ease of installation;

- guaranteed mechanical resistance;

- cheap and easy;

- it is easy to carry whether for transportation (be careful - so that the leaves do not travel one on the other, otherwise there will be tatters).

Disadvantages:

- bad soundproofing;

- There are plenty of options for installation.

Slate (asbestos-cement sheets)

Combining 15% asbestos with 85% Portland cement, we see a flailing slate sheet of standard dimensions (1.2×0.7 m, slate height less than 3 mm). The leaves are fastened with flowers, and gum pads are placed under the droplets (the slate easily collapses when hit with a hammer). Before installation, the slate must be treated with waterproofing from roofing material or similar material.

Pros:

- cheap;

- good cutting.

Disadvantages:

- crankiness;

- unkind for people;

- unsuitable for covering a booth;

- It hangs for a long time, through which it absorbs the growth of fungus and moss.

Metal roofing (corrugated sheeting, steel, copper, aluminum seam)

Corrugated sheet

Manufactured from hot-dip galvanized steel, which is then profiled or corrugated to increase rigidity. This is the simplest type of pokritya dahu. Such material will stiffen at any temperature of 10 degrees or more.

Pros:

- high ease of installation;

- high value for money;

- high durability;

- cheapness.

Disadvantages:

- Soundproofing is bad.

All leaves are smooth steel. Pleasant temperature at 20 degrees to maximum. Attach the sheets one by one behind additional caps and a jug sheet. The seam between the sheets is called a fold. This type of roofing can be used on churches, old gardens and industrial buildings.

Pros:

- do not burn;

- bendiness;

- You can charge a fee.

Disadvantages:

- weak ability to strike;

- there is a need for additional insulation.

Copper and aluminum seam roofing

This is durable, attractive, and, as a result, expensive roofing material. Ale tse vipravdano. Copper loses its plasticity due to negative temperatures. In addition, over the years, under the influx of carbon dioxide vapor and atmospheric fallout, the copper becomes covered with a patina - a brown-green scum that protects the material from corrosion, mechanical damage and ultraviolet radiation. Aluminum is also coated with a dry coating.

Pros:

- resistant to burning, corrosion, and acidic deposits;

- environmentally friendly material;

There is only one minus: expensive.

Wine is composed of cellulose fibers, infiltrated with bitumen and enriched with resins, additives and pigments to enhance flexibility and preserve value. Criticism with such material can already be done with a slight difference of 5 degrees to the maximum. Ale at minimal damage It is necessary to work on overlapping the sheets of 2 sheets.

Pros:

- light material (lighter than slate and metal tiles);

- plasticity makes installation on folding trucks easier.

Disadvantages:

- burns, blooms;

- shilny to the mountain;

- weak frost resistance (25 cycles).

Whatever it is, it doesn’t matter, be it lifeless private booth, cottage or Gospodar's cabin, will require the correct choice and installation of roofing. Where to lay down those who can tolerate the negative influx of natural factors, as well as the terms of their service. Therefore, it is so important to choose the right and suitable coating materials for your home, as seen in the prices presented in this article.

It is important to correctly determine the type of coating material needed

Coating materials for dahu: see and prices for different light and chemical manufacturers

There are a lot of options for coating materials, which differ among themselves according to their use and authorities. Some are the best option for covering residential premises, others are suitable including objects of government significance.

Metal tiles for houses: types, options, sphere of compaction

This material is one of the most popular among the current household coating materials for households (see the prices shown below), and is not uncommon, even in addition to the important operational authorities, in May garnium external look.

It is made from steel sheets of various grades, coated with special coatings that resist the appearance of dents, smudges and other deformations such as rubble and stone. Finally, damage to the coating may result in corrosion, which will significantly reduce the service life of your coating.

Besides a standard galvanized steel sheet, the basis for metal tiles can be other metals that are easily damaged:

- Alyuminieva The tiles are generally of low quality, to which factors such as resistance to corrosion and lightness can be added. In addition to this decision, high quality and a wide range of colors are important.

- Mid As a material for covering, it exhibits such advantages as durability and reliability, and in addition, it truly offers the best solutions. As on any other copper surface, a green coating will soon appear on such a surface, which protects the metal from deterioration in the same way as polymer coatings.

It is clear that there are very few design solutions in the field metalevikh dakhіv, each skin has its own characteristic rice:

- The great popularity of light transmitters is due to the covering Monterrey , whose shape suggests the original clay tiles.

- Profile Cascade Its shape resembles a chocolate bar and is perfect for coating a folding shape. This solution is optimal for those who want a strict, laconic, classic style.

- Profile Joker The coating is similar to ceramic and has smooth curves, and is also considered one of the basic, traditional coating options.

- Profile Banga It was only recently that the everyday life began to gain popularity, but now it has become possible to conquer the shanuvalniks with a completely non-standard form of high tail, which creates a trivial image.

- Andalusia As the first option, which appeared on the market not so long ago, it has established itself as a clear tile that replaces the fastenings of Monterrey.

- Shanghai Brought to Russia by Chinese robot workers, it has a folding geometric shape.

Metal coverings for dahus: see and prices for them

| Image | View | Average price, rub/m2 | |

|---|---|---|---|

| Metal Profile | Monterrey | view 345 |

| Maxi | view 345 | ||

| Standard | view 340 | ||

| Grand Line | Classic | view 304 |

| Modern | view 209 | ||

| Kvinta | view 338 | ||

| Ruukki | Finnera | view 660 |

| Monterrey | view 490 | ||

| Elite | view 1260 | ||

| Armorium | type 815 |

Corrugated sheeting: scope of vicorization, particularities of stagnation.

Corrugated sheeting is made from the same material as metal tiles, and is used mainly for government and industrial purposes, for example, for covering sheds and shops. Due to the technology of its production, such material, with proper installation, will last up to 50 years.

Advantages of using corrugated sheets:

- resistance to corrosion, unfavorable natural spills and mechanical deformation;

- trival term of service;

- ease of installation through the manual form and lightness of the design.

Respect! Corrugated sheeting, as well as metal tiles, may high rhubarb noise, which will require additional sound insulation.

| Image | Name of the company-producer | View | Average price, rub/m2 |

|---|---|---|---|

| Covering season 4 Polyester | C8 | 240 |

| C8 | 558 | ||

| Cover for season 4 Printek | S21 | 275 |

| S21 | 669 | ||

| Grand Line Atlas | C8 | 436 |

| S21 | 497 | ||

| H60 | 580 | ||

| CH35 | 496 | ||

| Grand Line Velor | C8 | 450 |

| S21 | 514 | ||

| H60 | 599 | ||

| CH35 | 513 |

Article on the topic:

In addition to the publication of presentations, a report on the inspection of this roofing material and tricky installation steps.

Ondulin: natural material for coating

Ondulin is used for sheet coatings, which is formed on the basis of cellulose, infiltrated with polymeric resins. The top of the ondulin is prepared with a special mixture, which is resistant to heat.

Advantages:

- naturalness, ecology and safety;

- good indicators of viscosity;

- simple installation, little effort, ability to cut the material using a simple hacksaw;

- absolutely silent;

- budget prices

| Name of the company-producer | View | Average price, rub/m2 |

|---|---|---|

| Ondulin France | green leaf | 455 |

| Arkoush chervoniy | 437 | |

| Leaf brown | 437 | |

| Arkoush zinc | 370 | |

| Red ridge element | 288 | |

| Ondulin Russia | green leaf | 328 |

| Arkoush chervoniy | 331 | |

| Leaf brown | 331 | |

| Ridge element brown | 308 | |

| Red ridge element | 308 | |

| Green ridge element | 321 |

Seam cover for a private booth: see the price

This material is a formed sheet of steel, coated with a ball of zinc. Often, elements of enhanced protection against aggressive infusion of the middle are also coated with special polymer layers. In this way, the seam covering covers the surfaces that are formed by sheets fastened together.

Types of similar material:

- single elements;

- standing;

- second;

- recumbent

Advantages of the rebate wicker:

- intolerance to low temperatures, risk of injury;

- high flexibility and low moisture, which allows installation of windings in folding-shaped drains;

- aesthetics, brevity.

| Image | Name | Cover type | Average price, rub/m2 |

|---|---|---|---|

| Self-locking fold | Galvanization | 316 |

| Polyester | 419 | ||

| Atlas | 529 | ||

| Velours | 544 | ||

| Quartzite Light | 594 | ||

| Double standing seam (Profi) | Galvanization | 274 |

| Polyester | 363 | ||

| Safari | 516 | ||

| Velours | 473 | ||

| Quartzite | 652 | ||

| Hinged standing seam | Galvanization | 274 |

| Polyester | 363 | ||

| Atlas | 459 | ||

| 595 | |||

| Velours | 473 |

M'yaka covering for dahu

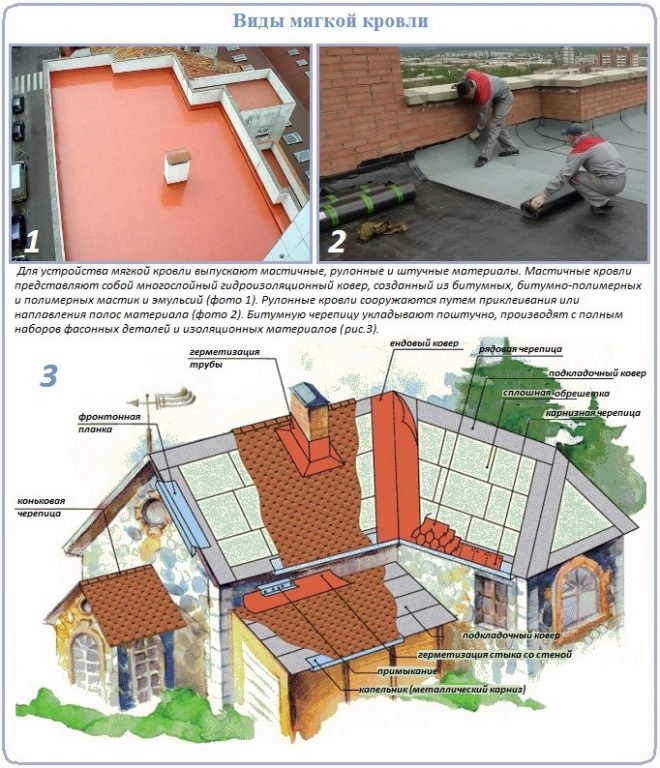

There is a whole series of criticisms that go up to, materials, , mastic, polymer membrane, various roll materials.All of them have the following positive powers:

- intolerance to the negative influx of weather minds, various deformations;

- Simple installation that does not require any special skills or knowledge.

- Povna fire safety, noise insulation;

- trivial term of exploitation.

Important! From all types soft cover Everything is fireproof except for roofing material.

Below is a table containing information about soft roll coating: see the prices on it.

The price of soft covering is for 1 sq. meter (myaka tiles)

| Brand name | Image | Product name | Average price, rub/m2 |

|---|---|---|---|

| Tegola (Top Shingle) |  | Futuro | 299 |

| Smalto | 238 | |

| Prime Minister | 455 | |

| Vintage | 273 | |

| Shinglas |  | Quadrille Sonata | 1150 |

| Quadrille Chord | 1150 | |

| Ridge-cornice | 1860 | |

| MIDA |  | Quadro | 510 |

| Prima | 645 | |

| Acord | 710 | ||

| Trio | 710 |

Robimo visnovki

Correctly selecting the optimal coating materials for your home, as seen in the prices shown above, is a significant task that conveys careful attention to various types of information, reviewing videos and photographic materials. A video that can help you with your search is presented below.

Ideal waterproofing in combination with simple installation shows the class of soft coating materials compared to analogues made of ceramics and metal. The price is right. You are certainly pleased that the share of independent carriers is lighter in the countries that are being developed. The flexibility that always comes into play is super-folding, and sometimes fantastic projects. All types of soft coverings with different levels of activity are required in private everyday life. The area of stagnation depends on its structural specifics and warehouse. It is important to become familiar with the technical aspects that indicate the installation scheme and the future prospects before purchasing the material.

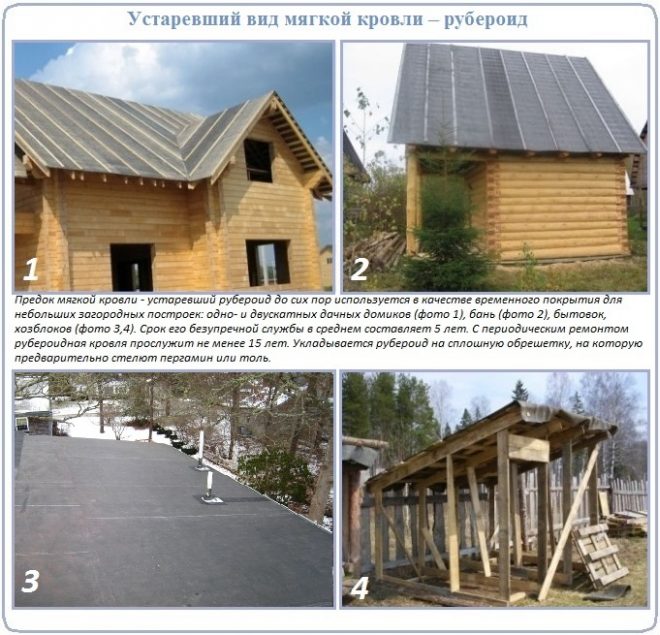

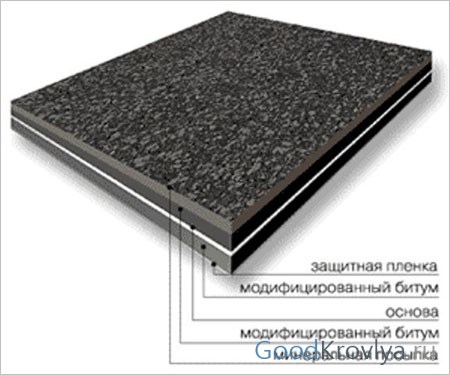

The progenitor of the family of soft roofing materials was rolled roofing felt, created by applying naphtha oxidized bitumen onto a cardboard base. Both components did not control the wear resistance. Under the pressure of atmospheric precipitation, the cardboard swelled and collapsed, the bitumen cracked, resistant to frost. The weak resistance to the vagaries of the weather has worn out the paths to perfection.

The old warehouse was modified with polymer warehouses. Polymers improved durability, increased elasticity, and provided resistance to climatic disturbances. Cardboard, which did not inspire success, was replaced with materials that could rot: creases, glass fibers, beaded fabric, polyester fabric, corrugated copper or aluminum foil. Insanely, refinement appeared on Vartosta, and next to it they significantly increased the term for the service of coatings that constantly contact with our external environment. Repair and replace a new soft roof 3-5 times faster, lower roofing material and only for the sake of which you can save money.

As a result of diligent work on the decorations technical characteristics Materials appeared that were structurally similar to the forefather's, but they outweighed it for aesthetic and operational reasons. Since previously rolled materials most often served only as waterproofing, now they can successfully combine this additional function with additional bindings. And, as before, knock on the rolls. Vibrate for additional application to the base, which does not rot, bitumen-polymer or flattened bitumen warehouses.

The surface should be protected with a mineral coating, and the back adhesive side should be reinforced with a sponge that prevents gluing of the coils of the roll during storage and transportation.

Cream of roll products, the clan of modernized roofing felts has been replenished with new representatives:

- Mastics and emulsions, which are released in a paste-like and sour cream-like consistency. It is impossible to say that there would be unknown options, unless updates were introduced. Previously, stench played the role of a coating waterproofing agent or a preventive agent for roof pyrolysis. Infectious stench can occur as an independent roofing coating. Apply it in 3 ways: sawing, splitting with a spatula or pouring. Place in balls, encased in reinforced shells, and on the slopes. The result is similar to the roll counterparts that are produced directly on site, and not on the production lines of the production plant. In essence, this is a bitumen, polymer or bitumen-polymer coating, which was not applied to the base in advance;

- Polymer membranes, which is supplied in traditional rolls. The prepared membranes adhere to the structural principle of roofing material, and also have the same properties in storage. The polymer component PVC, TPO or EPDM is applied to the sides of the reinforcing mesh. In the warehouse of the polymer casing, there is a survivable component of the material and a laying scheme for the coating;

- Asphalt shingles, Which is a cutting of roofing material into leaves. Virobnitstvo clay tiles The manufacturers themselves are engaged in producing coating materials in rolls. In addition to the tiles, shaped parts are created, which allows for complete finishing of any size or shape. Piece material is characterized by less elasticity, lower roll material, because There are no appointments for the ranks similar to the scale of the task. However, private everyday life itself is extremely popular.

The following types of soft coating can be used for coating at different levels of hardness. With the help of mastic and rolled materials, it is important to glaze flat and low-profile structures. These may be low-surface units in the techno or high-tech style, solid canopies over arrival terraces, a great gank with thick columns, a bay window, a veranda.

Small cabins in a classic, country or colonial style prefer to be “friends” with bituminous shingles, which have roofing ceramics, shingles and natural slate.

A look at the bunk roof coverings

The area of laying out different types of soft coverings is closely related to the technical features and installation method, which ensures a competent choice of material.

Type #1 - roll of bitumen coating

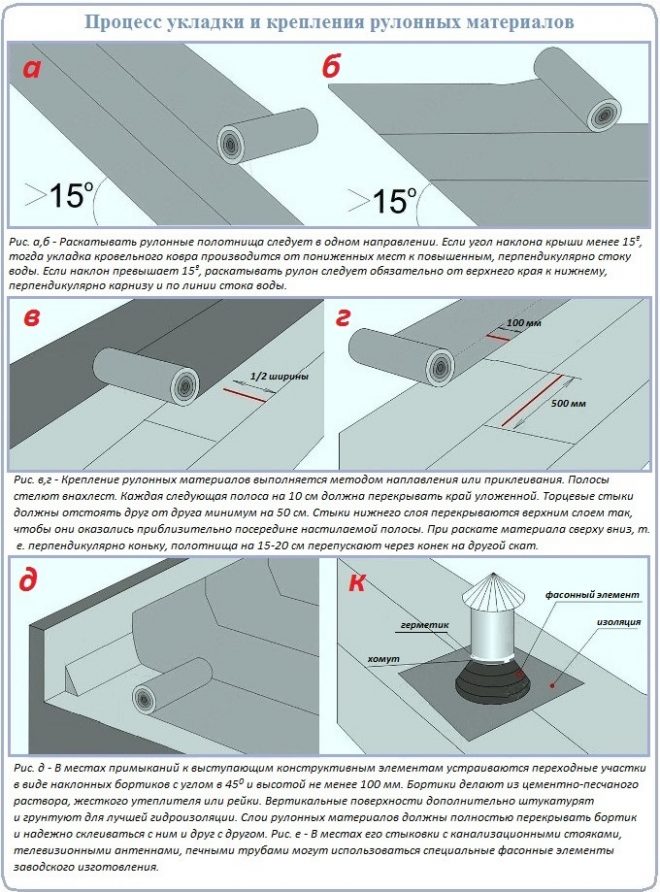

Before the outlet of the BITUMNYKH Pokryvelny, the scrolls of the same, the noum-captured Generalnnya Ta Materei, the modifimal warehouse, the Suttyvikh viDmi is not to be spontaneous. They are arranged in a similar order.

There are 4 methods for fastening bitumen and bitumen-polymer roll roofing until the base hardens:

- Glued to hot mastic with a friendly bitumen or bitumen-hum warehouse. Checks, but an outdated method that requires expensive mechanization of the process for preparing astringent speech and the obligatory part of a brigade of intelligence officers. The covering is arranged in 4-5 mutually perpendicular balls;

- Glued to cold mastic type “Visher”, which perfectly coats the coating with a primed base. The method can only be applied to materials up to 2.8 mm thick. The mastic is applied with a smooth ball not on the base, but on the coated piece of paper that is attached, about 50 cm deep or on the entire sheet. After fixing the smudge on the designated area, carefully rub the surface with a silicone roller to remove the surface and excess adhesive material. The process involves at least two coating agents: one applies mastic and rolls out the roll, the other rolls from the middle of the attached canvas to the edges. I do this until the installation is complete;

- Cold welding. Preparations are being made for further breaking up the thickened bitumen ball from a resistant material. The lower surface of the sheet placed before laying is sprayed with gas or white alcohol. The retailer should also apply it to the previously prepared primed base. Smugs are fastened as standard with an overlap of 10-12 cm on the sides and 15 cm in the end joints. Laying by this method can be done by one end, otherwise you will need to work at a very fast pace;

- A welding process that consists of a path of fusing a melted or heated material into a ball with a base coated with bituminous mastic. Melt the back side of the coating with a thickness of 2.2 to 5.0 mm with gas fins, through which part of the casing burns and easily wears out in terms of wear resistance. Moreover, the wrathful way to survive is not safe through the threat of fall attacks. Heat with more gentle infrared heating pads across the entire width of the sheet. Laying down for at least two people. One step rolls out and melts the surface of the sheet along the entire width, the other presses it with a silicone roller to the surface.

We have not indicated the method of fastening self-adhesive bitumen and bitumen-polymer rolls. Let it sit until a thin insulating ball with a thickness of 1.2 mm is laid, which does not cover any surfaces.

The roll coatings are laid on a flat roof from the middle of the platform, protruding in both directions to the periphery. The coverings are melted and glued onto the slopes, sticking out from a point along the slopes uphill. As in the relief of the roofing there is a structural reduction: grooves, internal drainage objects, etc., laying is carried out starting from them. Before work, barrier waterproofing is applied to the sections of the roof, so as to recognize the greatest importance, to them there are grooves, sharpening of communication passages, contact, and the edge of hangers.

Before attaching it to a flat surface, unroll and try on the roll. Before laying, burn to the middle with the back side facing up, so that the flat structure will be distorted. How to get rid of it pitched roof, the pile of material is liable to end up at the bottom point of the working maidan. The rolled material is laid in smuga with an overlap along the later lines of no less than 10 cm, in the end tapping area there is an overlap of 15 cm. As a result, you can end up with a pallet with sides with a minimum height of 30 cm.

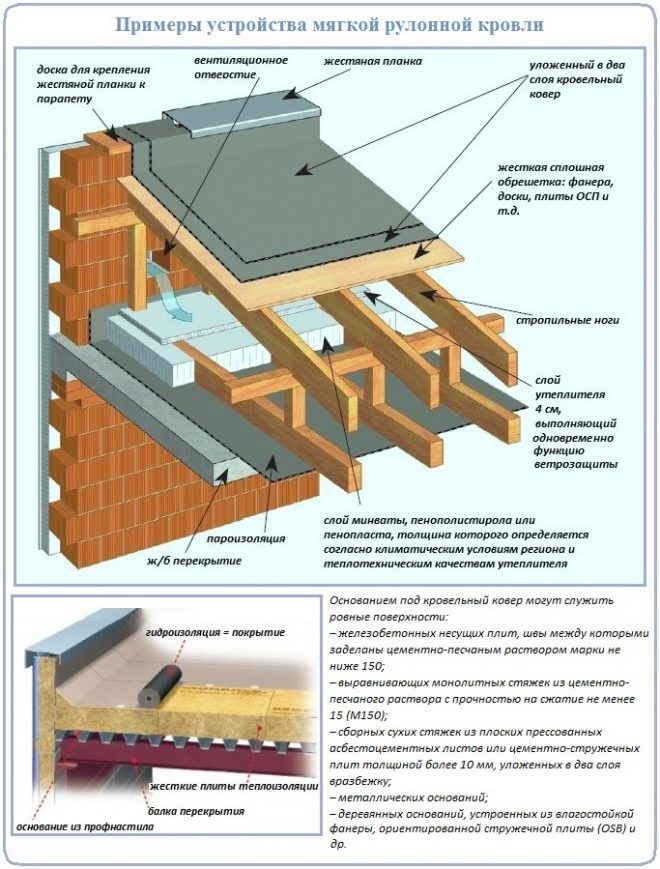

The base for laying the rolls can be concrete screeds, poured with or without reinforcement, concrete slabs, corrugated sheets and plywood sheets or OSB slabs. The rules for installing soft roll roofing dictate the number of balls of coating that must be placed against the steepness of the roofing structure:

- laying in 2 balls should be made if the steepness of the slopes is more than 15 º;

- lay 3 balls, depending on the thickness from 5º to 15º;

- Apply the coating in 4 balls on absolutely flat surfaces and roofs with slopes up to 5º.

It is permissible on slopes with a slope of up to 25º. Laying on a slope of more than 15º is followed by spreading the leaves directly to the flow of water along the skhila, then. parallel to the bloody legs. However, those who want to go to the designated method are rare units. Rolls are preferred for laying on flat surfaces where other covering materials cannot be installed.

Type #2 - mastic or self-leveling coatings

Regardless of the apparently high quality of the materials, the application of soft mastic paste from polymer, bitumen-polymer and bituminous mastics is cheaper, the lower cost of coating from roll coatings is similar to the warehouse. All on the right is the sectional mechanization of roofing robots. Mastic coatings, also called self-leveling ones, have one very important plus - the monolithic coating rim does not have seams that are identified as potential zones for leakage.

There are some drawbacks: it is very important to form an even ball. The other small part lies near the soil until the base is wet. Neither wet nor hairy is to blame, which imposes implications on the choice of climatic period for installation. As weather forecasters predict that there will be a fall after the installation is completed, the work will probably not begin.

A molded mastic coating may have the same type of material or a combination of materials. For example, emulsion balls can be mixed with rolled coating balls. Based on design characteristics, mastic roofing materials are divided into 3 types:

- Unreinforced, Create a sawn bitumen-latex emulsion, on top of which apply a ball of hot mastic mixed with gravel mixture;

- Armovani, Formed with balls of bitumen or bitumen-polymer mastic. The leather ball of the roofing kilim is reinforced with spun cloth, spun fiber or spun cloth;

- Combined What is the drawing of mastic balls and rolled balls. As the top protection of the combined coating, the vikorist material is rolled.

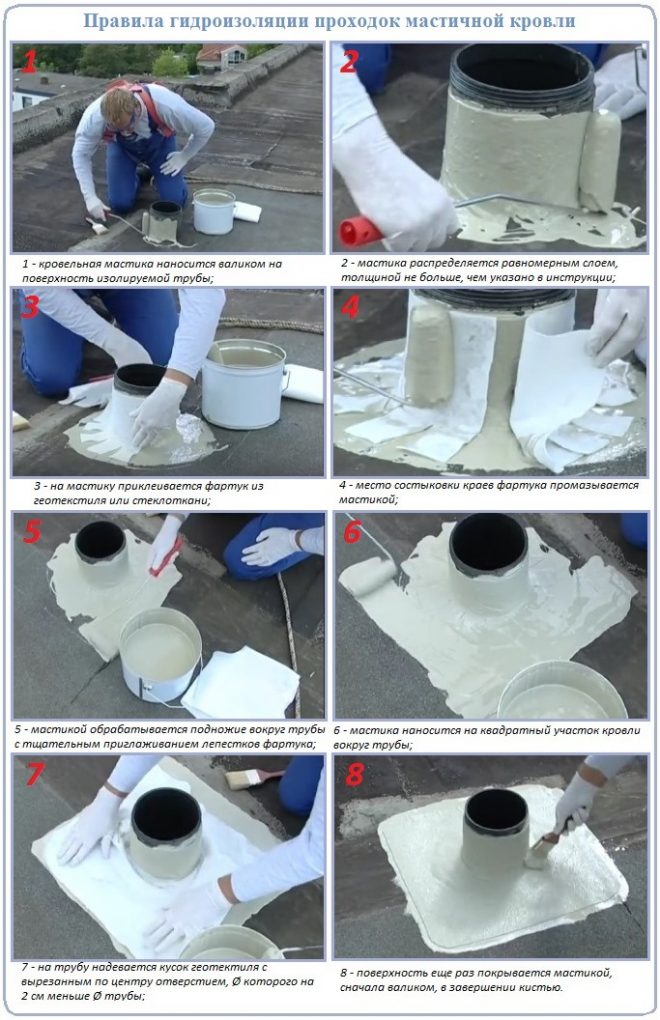

Typical algorithm for laminating reinforced mastic roofing:

- The weakened sections of the previously cleaned roofing are covered with a waterproofing barrier keel 50 cm wide, which is nailed or glued along the grooves, near the points and along the lines of the roof gutters, along the edges of the hangers. . If there is a bunk, it must also be protected with dark waterproofing 1.0 m wide;

- Around the flue pipes and the vertical wall roofing line, apply an insulating coating following the pattern of contact with the flowing curtains from the tricut in the cross-section of the slats or rounded cement curb;

- The vertical walls of the parapets and the junction are pasted over with horizontal stripes to a height of approximately 30 cm;

- Apply mastic with a 0.8-1.0 cm ball onto the slanted vertical plot by hand with a spatula;

- A ball of primer is applied to the coating base using a sawing path. The emulsion mixed with chopped glass fibers is fed under the pressure of a gun. In the absence of obvious conditioning at home, you can apply the first ball using another method: fill it with emulsion and reinforce it with crushed rolled gravel or mineral crumb;

- Another ball is placed after the filling has completely hardened. The plot is covered with dark reinforcing fabric with an overlap of about 10 cm on the vertical wall. Then the selected type of material is applied. The recommended ball size is 2mm;

- The steps are repeated until the coating is formed according to the planned work. To finish, apply a ball of cold bitumen-latex emulsion or hot bitumen-hum mastic or fry.

The work of washing the mastic kilim begins from low sections of the roof, reaching through to the upper points. A galvanized metal strip is installed on the sides along the vertical walls to protect the top edge. The cornices are protected with a galvanized apron.

In order not to be spoiled by the choice, you need to carefully plow through the mastic coating so that it can be applied to the roofing structure that is being coated. It is necessary to cover the mass of material that falls on 1 m² and the thickness of the roofing system, therefore:

- Flat roofs and roofs with a cover of up to 2.5º need to be equipped with a kilim and 4 balls with a final gravel covering;

- Low slopes with a fringe at the boundaries of 2.5 º - 10 º are covered with a kilim of 3 balls;

- Slopes slightly steeper from 10º to 15º are protected with 2 balls of mastic coating with reinforcing holes;

- The slopes with a steepness of 15 to 25 are rolled with a keel using 3 balls of mastic, 2 balls of reinforcing material and dry food to the animal.

The base for the mastic coating is concrete screeds and slabs, the seams between which are filled with bituminous mastic. The base should not be primed from behind, but carefully prepared: remove the humps, fill the shells with rubbish, and scoop out the fatty patches. It is acceptable to add 5-7 mm to the relief of the surface of the base, but it will still need to be filled with mastic.

Type #3 - roll polymer membranes

Coating membranes are represented by a wide range of materials consisting of a rot-resistant reinforcing base and a double-sided polymer shell. It is clear to them:

- PVC membranes, Made on the basis of polyester mesh with a plasticized polymer coating. It is most common to fasten to the base using the adhesive method using cold mastic or a glue warehouse. One canvas is smoky due to the heat of the hot wind. If you want to install a soft membrane coating with your own hands, you can quickly use the ballast method, whereby the sheets are laid loosely and simply pressed with ballast onto pebbles, gravel, concrete slabs or paving slabs. To make the process of fastening PVC sheets easier, there is a telescopic fastening with a wide flat plastic support and a self-tapping screw in the middle of the fastening system;

- EPDM membranes with a polyester mesh base and a double-sided synthetic rubber shell. Fastening to the base and joining of the canvases is carried out only using the adhesive method. This fact is known to a small number of rolled rubber coatings, because the adhesive connection is compromised for the reliability of welding;

- TPO membranes with a base made of woven fabric or mesh and a shell made of thermoplastic olefins. How the PVC is attached to the base by gluing it with mastic or glue, and welded into the fabric.

In low-surface household items, PVC membrane coatings are often used, which simultaneously play the role of waterproofing and decorative material. They are produced in a wide range of colors, which is important for a private home. Analogues of TPO brandings are sacrificed according to design criteria, which is often due to banal insulation in roof pyrolysis.

If you need to cover the walls with a folding configuration, elastic EPDM material is suitable. Lay the membrane on concrete screed, for varnishing from boards, plywood, OSB sheets, on sliding boards and old waterproofing.

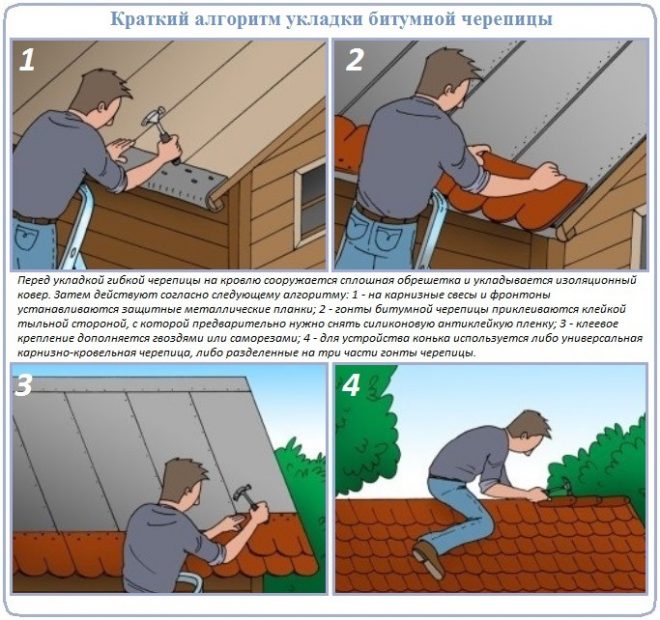

Type #4 - piece bitumen shingles

Gnuchka tile is an uninterrupted leader in the family of soft roofing materials, especially in the sphere of private life. It covers almost all pitched roofing structures, regardless of steepness. The piece material shares the aesthetics of the ceramic prototype, the insulation value of the rolls and the solidity of the self-leveling coating, so that under the influx of sleepy exchanges, the edges of the warehouse coalesce into it dark curve

Lay them on solid planks, plywood or OSB flooring, starting from the bottom and reaching up to the shed. Do not coat the base with mastic or glue, because Gatehouse tile shingles is equipped with an adhesive warehouse. The flooring should also be equipped with a lining waterproofing keel. The plots are suitable for intensive avantagement: grooves, cornices, ridges, ridges, contacts are coated with additional waterproofing protection.

The nuances of creating such a soft coating and the installation process can be seen in the video:

In the presented inspection, not all layers of roofing materials and their delicate installation have been overhauled. This is just information for the first time to get acquainted with information about technical features and technological capabilities. However, we tried to put it directly in the search and selection of the roof covering.

Nowadays, the coating needs to not only finish the drying function of all the fallout, but also to add to the current appearance of the former, the fading appearance is still complete Yu.

Many rulers were in The rest of the time attach especially respect very rich in decorative elements. And the clearly designed cover can be easily changed to make it unshowy.

To achieve this, the coating needs to be determined already at the design stage. Here it is necessary to be especially respectful before the process of future exploitation of all things. Incorrectly selected covering on the booth can lead to a change in the terms of operation of all beds. Even the design of the design can be applied to the entire wake-up call.

Metal

Metal tiles and corrugated sheets occupy leading positions in popularity among wealthy people, be they any other. It consists of sheets of profiled metal, which can be made of stainless steel or coated with a special wear-resistant porcelain. There are also a number of obvious advantages, including, first of all, ease of installation and high value of the coating for the device.

However, there is a significant shortfall associated with noise effects due to falls. This is especially beneficial when summer rain and hail fall on the roof. Because everything that happens on the street actually ends up right at home. But this problem persists.

To avoid all the sounds of the street, you should simply carry out clear soundproofing at the stage of installing the grille system.

Ale smut, what else will I add richly – price. I don’t mind spending large sums of money on such material. Also, don’t forget about those that when you cut off excess material, you just have to throw them away. It’s a pity that we can’t get anyone in.

Suchasny slate

A type of European slate used as an ondulin coating for a house made from natural materials. Your warehouse contains cellulose. To create a larger fortification, the leather sheet is coated and infiltrated with a special polymer deposit.

An obvious advantage is that it is possible to use such a structure that may result in an uneven lathing structure. This is especially true for people who are about to live out the Great Century.

The material is very elastic and flexible. Well, installation is definitely not the source of any problems. Ale, I don’t care about such a plus, the vaga of the skin sheet is significant. Approximately close to 7 kilograms.

Considering its non-vibration, such a coating can be used for garage bedding. With such a structure, the roofing material warehouse can be allowed to be adjusted with a layer of over 50 centimeters.

Representatives of the “greens” will, before speaking, be pleased. Adje ondulin is produced from environmentally friendly and safe materials. Moreover, regardless of the obvious importance, it is difficult to work with additional special tools.

You can easily prepare leaves in almost any shape. Therefore, you can easily create original revisions and easily adapt sheets one by one.

Ale through bitumen warehouses in summer period Yes, he begins to show his obvious shortcomings. Even such material begins to soften and smell. This is then allowed to accumulate until the organic matter accumulates, and you can grow for an hour, as grass or moss begins to grow right there. Therefore, you need to clean it periodically.

The simplest material

Slate material is one of the brightest representatives of materials that offer maximum fire resistance. It is difficult to get through the warehouse when laying it down. Even when used with metal, it does not have any special softness. Therefore, it is necessary to show caution. If the leaf is cracked, it will have to be mercilessly thrown out.

Another major drawback is the presence of asbestos-contaminated substances. The stench is toxic and it is not possible to inhale the cut material if it disappears.

Until then, the wine will accumulate in the vologu. Hygroscopicity is especially beneficial during normal use. Covering with slate requires the use of such technical devices. For example, this could be a technical shed or an ordinary outdoor toilet.

New technologies: soft coating

Myaka cover the rest of the time also began to actively vikoristovuvatsya under the protection of rich private and commercial businesses.

Regardless of the garish external appearance, it is difficult to install. The obviousness of the decision is made only from the whole material. The shingles on the soft cover conveys the brilliance of a song - obvious to the noise. Even so, the coating of the glass itself already becomes part of the sound insulation. Due to the porosity of the material, it can be safely placed on the attic floor.

The quality of the material is not much more expensive than basic metal profiles or siding. Then, with a special texture and color scheme, you can create the right kind of art.

Particular coating: seam coating

The seam cover is covered with long metal sheets, which are used for special protection. In replacement of shingles, such material immediately falls into its place.

It’s very common for me to put copper in my warehouse. This corresponds to the maximum term of service.

However, due to the folding of the gina, which connects the vascular leaves, in case of mechanical deformation, even folding is avoided.

![]()

Exclusive option: soft tiles

You can also replace the shingles with vikorist to create a more beautiful tile coating. Otherwise, the softness of the roof covering requires even more problems during installation. For such a soft coating, a special lathing structure is required.

The price does not correspond to the validity of such a coating, because, to the point, it does not give enough attention to the structure of a typical slate. Although, of course, the fellowship is much greater.

Padded pouches

Whenever possible, it is necessary to firstly give respect not only to the appearance, but also to the virtuousness. Even when covering a roof like a slate roof, it can cost you a lot of money. Therefore, it is necessary to be diligent in approaching this food.

It is clear that the roof is necessary for the normal functioning of the house and quiet living in the new one. In order to be reliable and airtight, the trace should be vicorized clear materials for roofing work, the technology of their installation must be adjusted. The types of coating materials that everyday supermarkets sell, make sure you choose the most suitable option. To understand which of them is more likely to be chosen in certain minds, let’s look at the main performance characteristics, advantages and disadvantages of the most popular of them, as well as selection criteria.

When choosing a material for covering, it is necessary to take care of it as a matter of particular importance. The following factors are priority:

- Navigation on the data under the hour of operation. The design is responsible for preventing the loss of moisture and the amount of snow cover, which can be in the range of 70 – 180 kg/m2. The strength of the wind in the region can also be compared to respect.

- Features of the architectural design: shape, dimensions and roofing design are influenced by the choice. For example, non-leather material for covering the doors is suitable for complexly curved ceilings. Likewise, you can always create a dish out of a small kuthulu.

- Durability and fire safety. These parameters must be carefully taken into account in view of the following: for sovereign life, immersiveness is important, but the important term of service to the barn is not the initial parameter.

On the current Russian performance market great choice covering materials for pitched roofs of private cabins and cottages

- Warranty terms, when using any materials for covering the product, will achieve the same function. Metal tiles are expected to last from 5 to 15 years (depending on the coating), in which case the guarantee does not extend to the level of surface smoothness. The guarantee for ceramic tiles is up to 30 years (except for the parameters of frost resistance and the infusion of acidic meadow). Asbestos-cement slate will last at least 10 years. Bitumen – 15. Galvanized steel and corrugated sheeting – up to 20. Slate and seam roofing – 40 and 20 roofs in a row.

- The active terms of the service may be changed several times. For example, soft tiles and metal tiles can reliably serve up to 50, natural ceramic – up to 150, slate – up to 40, bitumen – 20-25, corrugated and steel sheets – up to 50, slate-based roofing – 200, seam – 50 rocks .

- The “price-value” relationship: when considering the most important parameters to determine the material that is suitable for new minds to use, it is important to evaluate its practicality and performance. Most often, it is not enough to buy a prohibitively expensive one: it is easier and cheaper to replace it with a new one within an hour.

When choosing a material for a foundation, it is necessary to place it firmly on the foundation and bearing walls at home

What is the most common way to cry?

The coating material for showers must provide high value, chemical resistance, ability to withstand critical temperatures and not allow water to pass through. These authorities use materials for covering goiters for their own chemical warehouse that structure. Such materials are most often used for dahu budinku.

Select cover for economy class: video guide

They are prepared by molding and melting clay mass. During the processing process, the cheese is subjected to a temperature of about a thousand degrees, as a result of which the finished cheese acquires a dark-brown color. Before embossing, a special dry glaze is applied, which is necessary to effectively remove hair from the surface of the coating. Ceramic tiles are tiles measuring approximately 300×300 mm, weighing 2 kg or more. Vaughn is booming different shapes: stamped groove, groove and flat stitch, row, one-and-double, grooved.

It gets stuck when the slopes are steep at 25-60 degrees. They can be cooled at a temperature of 20-22 degrees, but only with additional waterproofing and ventilation. If the hilt exceeds the critical 60 degrees, the tiles must be fastened additionally with the help of bolts and screws. The sealing of other elements is carried out using special locks.

Ceramic tiles are a reliable and durable roofing material

There is also fixation on the edges, but in this case another “dressing” becomes stuck if the skin of the advancing element is often superimposed on the front one. The laid tiles create a strong waterproofing layer, which has a service life of 100-150 years or more. Through a significant gap, you can put together tiles to create any type of roofing structure without sufficient value. The price varies from 20 to 50 $ per m².

Among the advantages of ceramic tiles are vibration-free operation, high level of noise reduction, fire safety, resistance to low temperatures, the ability to create roofs that need to be ventilated, miraculous natural properties osti. Inadequacies – there is a lot of moisture and stiffness, as well as the need for vibrating when installing additional fastening elements.

Such tiles are shaped under pressure from cement-based mortar. Value less than its ceramic counterpart – 35-45 kg/m². When the mixture is prepared, sand and cement are added with salinity oxide for prefabrication. The result is a material that is functional and practically does not suffer from ceramic coating. Cement-painted tiles are produced: flat, profiled, glazed or without glaze.

Cement-painted tiles come in different colors.

Laying is carried out after the installation of the grating, the length of which is 600 to 900 mm. The solution to the process does not differ from the principles of laying ceramic tiles.

To achieve this, you should bring a rich color palette (which can be achieved by adding various barberries in Sumish), high value, which grows over time, and resistance to various external influences. iv (drowsy light, high temperature, fall). Costs less than ceramics: between $10-20 per m². Not long – significant thickness (10 mm or more) and crispness.

Bitumen shingles

This includes fiberglass, cellulose and polyester: they are applied to bitumen tiles, and then covered with barn. After it is laid, the ball of humo-bitumen coating is glued together under the influx of hot sleepy mixtures. As a result, a monolithic coating is created from elements approximately one meter long and 30 cm wide or more (weight ranging between 8-12 kg). There are bituminous shingles of rectangular, square, tricut and oval shapes, different colors.

Asphalt shingles have a lot of advantages: they are very plastic (which is ideal for covering folded shapes), which makes it possible to create a reliable, hermetically sealed roof with high-quality sound insulation. It does not wear out during transportation and is easy to install (with virtually no waste).

Bituminous shingles are suitable for coating folding roofing

It is necessary to tighten the tension at about 12 degrees. The installation is laid on a concrete frame made of OSB boards or moisture-resistant plywood on top of a lining made of waterproofing material. If necessary, the roof can be easily repaired. Not enough - high flammability, flowering, impossibility of finishing in the cold season of fate. The price of bituminous shingles ranges from 8 to 10 $ per m².

There are many similar coating materials, which are made from two sides of galvanized steel sheets protected with polymer coatings (polyester, acrylic, plastisol, PVF 2), which also maintains the same function, What is decorating? The color, texture and thickness (0.4 mm or more) of these coatings may vary.

Metal tiles and corrugated sheets - similar in structure and method of curing the material

Metal tiles can be used for roofing with a minimum angle of 15 degrees, corrugated sheets - 10 or more. When placed under less than 20%, additional sealing of the sticks will occur. Fixation is carried out using special fastening elements and sealing gaskets.

Metal tiles and corrugated sheets create reliable coatings and can be assembled to create roofs for any kind of disputes: from kiosks to large industrial facilities, from guardhouses to dacha budinochkas to the rich surface of the living budinki. Cost – ease of installation and relatively low cost (for the average – about $10 per m²), as well as high mechanical cost and ease of transportation (small cost – no more than 5 kg/m²). Disadvantages: high number of outputs per hour of installation, high thermal conductivity and low sound insulation.

This material is based on a composite made from Portland cement and short-fiber asbestos, the strength of which is given by asbestos fiber. It is prepared as straight-cut thin sheets measuring 1200×700 mm, with a weight of 10-12 kg/m². The height of the canopy is 28 mm, the number of cannons, most often, is more than six.

The laying of this covering material is carried out overlapping the surface of the covering - no more than 12-60 degrees.

The slate sheets are laid overlapping and secured with flowers until the bars are laid on top of the lining ball made of roofing felt or parchment. There is slate with a strengthened and identical profile.

![]()

Asbestos-cement slate is used to paint the main operational components of the material

The rest of the time we use slate to dry the roof of the ruler's walls. The reason is the lack of speech, like that of new, healthy people. In addition, this material is crumbly and unsustainable: moss and lichen growths appear on its surface over time. To preserve this and improve other operational components, the slate is prepared with special barvniks.

Positive advantages include ease of processing, sufficient value and low price (2-3 $ per m²).

Seam covers: steel, copper, aluminum

The creation of such a covering is based on the principle of mechanical joining of parts one by one. The resulting seam is called a fold, and can be single or double, as well as lying or standing. The seams are folded manually or using special electromechanical devices.

The steel roof can be protected with zinc coating or special coating. Copper and aluminum are not required for protection. The concrete is laid on top of anti-condensation lining and sheathing attached to the roof trusses. The cut of slopes is not to blame but less than 20 degrees, for which the maximum cut is not standardized.

Seam covering made from copper sheets has an aesthetically pleasing appearance.

Vikorist for any kind of bevels: for the shell of its flexibility you can create folding forms. Also, the positive properties of seam roofing materials include high mechanical strength, low moisture (no more than 5 kg/m²), absorbency and aesthetic appeal. The disadvantages are the same as those of other metal coatings: high thermal conductivity and low sound insulation.

Thickness of the sheets: the thinnest can be copper – 0.3 mm in diameter, steel – 0.5 mm in diameter, aluminum – 0.7 mm in diameter. The yield of overinsurance of roofing materials is approximately 5 kg/m2. Variety of prices: from 5 to 7$ per m² – steel, 15$ per m² – aluminum and 30-40$ per m² – copper covering.

Bitumen slate is prepared by molding cellulose fibers with infiltrated bitumen and special resins, which harden under high temperature and pressure. The milk warehouse also includes mineral additives and pigments. Arkush is approximately 2x1 m in size.

It can be frozen for overcrit from this angle at 5 degrees or more. Laying is carried out on top of the base, on a grating, the surface of which is selected in a layer from the corner of the hole. Zastosovuetsya to cover various budіvel for reasons.

Bituminous slate comes in different colors

The flexibility of bitumen slate allows it to be used for curved paths. Vaga yogo – no more than 5 kg/m2. Prior to this, it is also necessary to ensure the diversity of the preparation and the ease of installation. Disadvantages – loss of color due to burning, deformation under high temperature, flammability, low frost resistance. Bitumen slate costs $5-6 per m².

This natural material, created by nature, falls into the category of spruce. Thickness – 4 mm or more, dimensions – 150×200 and 300×600 mm, weight – up to 25 kg/m². The installation is laid on a wooden grating with slats, standing between them, but a little less than half the amount of the surrounding element.

These are spring and soft tiles that are easily chipped when prepared and laid. The material does not allow moisture to pass through, is resistant to temperature changes, frost and UV-proofing. The term of service is approximately 100-150 rokiv. The cost of 1 m² of material is around $70-80.

The slate roof is laid on joists made of wooden slats

Roll materials

Soft roofing materials - roofing felt and euro-rubbing felt are introduced to them, among others. The remaining one is simple and clear, with the help of which you can create a reliable coating that will last at least 15 years. Eurorubberoid is used for sealing the roofs of garages, government buildings, country houses: the natural stone mixture and rich spherical structure will be provided with fire mechanical protection.

The structure is laid on a solid concrete base, and is put together for the purpose with any kind of cut, whereby parts of the upper ball overlap with the lower one. Shorts: the quality is supported by the mountain and the aesthetic unattractiveness, as well as the foldability of the arrangement (the need to harden the pads). Positive versatility – low varity and light vaha.

The rich spherical structure of Euroruberoid will ensure reliable sealing of the roof.

In different ways The roofing can be sealed: roofing materials for which are either natural (slate, ceramics, and also exotic: wood, straw, turf), or sealed with a piece of material. Correct choice and laying the roofing material will prevent the normal functioning of everything. To avoid any problems that may need to be repaired, please contact the professionals for help. The following experts will help you choose and assist you during installation.